Production of ethyl alcohol from wood. Biofuel from the forest Technology of obtaining alcohol from sawdust

There is a growing demand for biofuels - flammable liquids made from renewable biological resources. One of them is wood. Is it possible to obtain fuel from wood that is not inferior to petroleum?

The first thing to understand is that it is impossible to make gasoline or kerosene from wood. It does not lend itself to decomposition into straight chain hydrocarbons, of which petroleum products are mainly composed. However, this does not mean that substances that can replace petroleum products cannot be obtained from it.

Some love the stool

The first on the list is, of course, alcohol. Two different types of alcohol can be obtained from wood. The first, which is called woody, scientifically, methyl alcohol. This substance is very similar to the usual ethyl alcohol, both in combustibility, and in smell and taste. However, methyl alcohol differs in that it is very poisonous, and its ingestion can lead to fatal poisoning. At the same time, it is a high quality motor fuel, its octane number is even higher than that of ethyl alcohol, and much higher than that of ordinary gasoline.

The technology for producing methyl alcohol from wood is very simple. It is obtained by dry distillation, or pyrolysis. More precisely, it is one of the constituent parts of the liquid - a mixture of oxygen-containing organic substances, separated from the freshly expelled tree resin. However, the yield of the alcohol thus obtained is too low to be used as a fuel. This makes such a technology for producing fuel hopeless.

However, ethyl alcohol can also be obtained from wood, in much larger quantities. This alcohol - the so-called hydrolysis alcohol - is obtained by the decomposition of cellulose, the main component of wood, with the help of sulfuric acid. Rather, the decomposition of cellulose produces sugars, which in turn can be processed into alcohol in the usual way. This method of producing ethyl alcohol is very common in industry; it is the hydrolysis method that produces almost all technical alcohol used for non-food purposes.

Ethyl alcohol can be used directly instead of gasoline, and as an additive to gasoline. These additives produce various types of biofuels, popular, in particular, in countries such as Brazil.

Obtaining ethyl alcohol by hydrolysis of wood is economically somewhat less profitable than obtaining it from various agricultural crops. However, the advantageous side of this method of biofuel production is that it does not require the allocation of agricultural land for "fuel" crops that do not give food products, but allows you to use the territories involved in forestry for its production. This makes the production of biofuel ethanol from wood a fairly practical technology.

And turpentine is good for anything

The disadvantage of ethanol as a fuel is its low calorific value. When used in engines in its pure form, it provides either less power or more consumption than gasoline. Mixing alcohol with substances with a high calorific value helps to solve this problem. And these are not necessarily products from oil: turpentine, or turpentine, is quite suitable as such an additive.

Turpentine is also a product of wood processing, and more specifically, coniferous: pines, spruces, larch trees and others. It is widely used as a solvent, and its most purified varieties are used in medicine. However, the timber processing industry as a by-product produces a large amount of the so-called sulfate turpentine - the lowest grade, containing toxic impurities, not only inapplicable in medicine, but also finds very limited use in the chemical and paint and varnish industries.

At the same time, turpentine of all wood processing products is most similar to petroleum products, more precisely, to kerosene. It has a very high calorific value and can be used as fuel in kerosene primates, lamps, kerosene gases. It is also suitable as a motor fuel, albeit for a short time: if it is poured into tanks in its pure form, the engines will soon fail due to tarring.

However, turpentine can be used as a fuel not in its pure form, but as an additive to ethanol. This additive does not greatly reduce the octane number of ethyl alcohol, but increases the heat of combustion. Another positive aspect of this biofuel technology is that turpentine denatures alcohol, making it unsuitable for ingestion as alcohol. And the social consequences of the widespread introduction of undenatured alcohol as a fuel can be dire.

Lignin waste - into income!

Such a component of wood as lignin is considered to be of little use. Its industrial application is much less widespread than that of cellulose. Despite the fact that it is used in the production of building materials and in the chemical industry, more often it is simply burned directly at the timber industry. However, as it turns out, lignin pyrolysis can produce more varied products than cellulose pyrolysis.

Lignin is mainly composed of aromatic rings and short, straight hydrocarbon chains. Accordingly, during its pyrolysis, mainly hydrocarbons are obtained. However, depending on the pyrolysis technology, it is possible to obtain both a product with a high content of phenol and related substances, and a liquid resembling petroleum products. This fluid is also suitable as an ethyl alcohol additive for biofuel production.

Technologies and installations for pyrolysis have been developed, which can consume both lignin from dumps and wood waste not separated into lignin and cellulose. Better results are obtained by mixing lignin or wood waste with debris consisting of discarded plastic or rubber: the pyrolysis liquid is more oil-like.

Peaceful atom and sawdust

Another technology for producing biofuel from wood was developed quite recently by Russian scientists. It belongs to the field of radiochemistry, that is, chemical processes that occur under the influence of radioactive radiation. In the experiments of scientists from the I.F. Frumkin sawdust and other wood waste were simultaneously exposed to strong beta radiation and dry distillation, and the heating of the wood was carried out precisely with the help of ultra-strong radiation. Surprisingly, under the influence of radiation, the composition of the products obtained during pyrolysis has changed.

In the pyrolysis liquid obtained by the "radioactive" method, a high content of alkanes and cycloalkanes, that is, hydrocarbons contained mainly in oil, was found. This liquid turned out to be much lighter than oil, comparable, rather, to gas condensate. Moreover, the examination confirmed the suitability of this liquid for use as a motor fuel or for processing into high-quality fuels, such as motor gasoline. We think that this does not deserve special mention, but let us clarify for the sake of calming the fears of radiophobes: beta radiation is not capable of causing induced radioactivity, therefore, the fuel obtained by this method is safe and does not exhibit radioactive properties by itself.

What to recycle

It is clear that it is preferable to use for biofuel production not whole tree trunks, but wood processing waste, such as sawdust, wood chips, twigs, bark, and the same lignin that goes to dumps and stoves. The yield of this waste per hectare of felled forest, of course, is lower than that of wood in general, but one should not forget that they are obtained as a by-product in the production processes that are already underway at many enterprises in the country, respectively, production waste is cheap and for them receiving does not need to cut down or plant additional areas of the forest for cutting.

In any case, wood is a renewable resource. Methods for restoring forest areas have long been known, and in many regions of the country there is even an uncontrolled overgrowing of abandoned agricultural lands with forests. Anyway, the Russian Federation does not apply to countries where forest conservation should be taken with care; the area of our forest and its potential for self-recovery is quite enough to fully utilize the timber processing industry, biofuel production, and many other industries.

Today, quite a lot of people are engaged in the manufacture of homemade liqueurs, but some drinks require an alcoholic element. Making alcohol at home is not very labor intensive. To do this, you need to know and take into account some aspects and principles of the manufacture of methyl alcohol.

First of all, the presence of grain is required for the manufacture of methanol. The role of grain crops in this case can be corn, wheat. You can also use potatoes and starch. But, as you know, in interaction with a substance, starch does not give any reaction. In order to produce a chemical element, the method of sugaring is used. And in order to sugar it, certain enzymes are needed, they are present in malt. By making ethanol from grain without chemical impurities, the yield of a natural product is observed.

Methanol production technology

The technology for the production of an alcoholic chemical at home can consist of several stages.

The most basic ones are presented below:

- Methanol production using malt. The grains of cultivated plants must be germinated in small vessels, while they are scattered in one layer, up to about three centimeters. Remember that pre-germinated grains must be treated with a solution of potassium permanganate. After processing, the seeds are placed in a container and moistened with water. It should be borne in mind that the presence of sunlight, or the sufficiency of light directly depends on the speed of grain germination. Cover the container with a plastic material or thin glass, that is, it must be transparent enough. If there is a decrease in the amount of water, it must be added.

- The next step: processing the starch. To begin with, we extract starch from the product that is selected for the manufacture of ethanol. In this case, it's potatoes. Lightly spoiled potatoes should be boiled until a paste forms from the water. Then we wait until the product cools down, meanwhile grind the malt. Next, mix the two products. Next, the starch splitting procedure takes place, it must be carried out at a temperature of at least 60 ˚ С. Now the mixture is placed in a bowl with hot water and left for 1 hour. After a lapse of time, the product is completely cooled.

- Fermentation stage. As you know, fermentation is characterized by the presence of alcohol-containing elements. However, mash cannot be called an alcoholic drink. After the mixture has cooled, yeast is added, which is capable of reacting even at room temperature. However, if the temperature rises higher, the fermentation of the product will naturally occur faster. In case of significant heat, the fermentation procedure will end after three days. At the same time, a mild grain smell can be felt from the product.

- The next step is distillation. How is it produced? For this, a special apparatus is used for the production of alcohol at home.

- The final stage is the cleaning technology. We can say that methyl alcohol is ready, but it is noticed that the liquid is not transparent. That is why cleaning is done. It is carried out by adding a solution of potassium permanganate. We leave the methyl alcohol in this form for one day, then we filter - the product is ready.

As we can see, the technology for making homemade alcohol is quite simple and does not require additional efforts.

Ethanol production from sawdust

In recent years, there has been a significant decline in the fossil raw materials that can be used to make ethyl alcohol. There is a shortage of grain. However, the production of alcohol from sawdust is not the worst option, as this raw product is constantly renewed over the years.

However, making a substance from sawdust requires some skills, and in addition to everything, the manufacturer must have special equipment, without which it will be laborious to produce ethanol. The production of alcohol from sawdust at home is very popular, so it does not require high costs.

As you know, your manufactured ethanol cannot be compared with the factory version. Household products are of higher quality, because each ingredient is unique. It is much easier to produce alcohol from sawdust!

How to make an alcoholic product at home?

The production of ethyl alcohol at home is carried out using a special apparatus. This device is capable of performing the procedure for the splitting of certain elements, as well as carrying out chemical reactions between them. Typical distillery equipment may look like mini factories. You can make any kind in them alcoholic beverages.

It is quite simple to study the technology for preparing an ethyl substance, while the product is obtained of high quality. What can you get from this? Firstly, these are high-quality alcoholic products, and secondly, their own costs are fully recouped, this requires a special apparatus.

For example, if sugar is used in the amount of 20 kg, up to 12 liters of alcohol comes out of it. In this case, the percentage of methanol reaches 96%. From this calculation, 25 half-liter bottles of vodka come out. In addition, the electricity consumed by the device will be consumed about 25 kW.

Such equipment is capable of using all loaded products as intended. The yield of non-potable product produced in the first treatment can be used as a cleaner for glass surfaces and windows. Also, such a device can be installed independently, using the necessary diagrams and drawings. Such equipment can easily cope with the production of methyl alcohol.

Equipment for the production of alcoholic products has some principles of its work. The device has a special neck that fills the tank with the required liquid. Mash can act in the form of such a liquid. Heating burners are used to heat the product to boiling point. After that, the apparatus and equipment must be switched to normal mode.

Further, cooling takes place through the refrigeration compartment with additional cleaning of steam from unnecessary impurities. The purified substance enters the tank, and the vapors go to the refrigerator, in which they are cooled to a liquid state. The apparatus for the production of alcohol is capable of working out the established standard. The result of this procedure is high-quality alcohol.

Hydrolysis of plant tissue polysaccharides in cold water is practically not observed. When the water temperature rises above 100 °, the hydrolysis of polysaccharides proceeds, but so slowly that such a process has no practical value. Satisfactory results are obtained only with the use of catalysts, of which only strong mineral acids are of industrial importance: sulfuric and less often hydrochloric. The higher the concentration of a strong acid in the solution and the reaction temperature, the faster the hydrolysis of polysaccharides to monosaccharides proceeds. However, the presence of such catalysts also has a negative side, since they, simultaneously with the hydrolysis reaction of polysaccharides, accelerate the decomposition reactions of monosaccharides, respectively, thereby reducing their yield.

With the decay of hexoses under these conditions, oxy-methylfurfural is first formed, which rapidly decomposes further with the formation of end products: levulinic and formic acids. Under these conditions, pentoses are converted to furfural.

In this regard, in order to obtain monosaccharides from plant tissue polysaccharides, it is necessary to provide the most favorable conditions for the hydrolysis reaction and to minimize the possibility of further decomposition of the resulting monosaccharides.

This is the problem that researchers and industrial workers are solving when choosing the optimal hydrolysis regimes.

Of the large number of possible variants of acid concentration and reaction temperature, only two are currently practically used: hydrolysis with dilute acids and hydrolysis with concentrated acids. In the case of hydrolysis with dilute acids, the reaction temperature is usually 160-190 ° and the concentration of the catalyst in the aqueous solution ranges from 0.3 to 0.7% (H2SO4, HC1).

The reaction is carried out in autoclaves under a pressure of 10-15 atm. When hydrolysis with concentrated acids, the concentration of sulfuric acid is usually 70-80%, and hydrochloric acid 37-42%. The reaction temperature under these conditions is 15-40 °.

It is easier to reduce the loss of monosaccharides during hydrolysis with concentrated acids, as a result of which the sugar yield with this method can reach almost theoretically possible, i.e. 650-750 kg of 1 T absolutely dry plant materials.

During hydrolysis with dilute acids, it is much more difficult to reduce the loss of monosaccharides due to their decomposition, and therefore, in practice, the yield of monosaccharides in this case usually does not exceed 450-500 kg from 1 g of dry raw material.

Due to the low loss of sugar during hydrolysis with concentrated acids, the resulting aqueous solutions of monosaccharides - hydrolysates are characterized by increased purity, which is of great importance for their subsequent processing.

Until recently, a serious drawback of the methods of hydrolysis with concentrated acids was the large consumption of mineral acid per ton of sugar produced, which led to the need to regenerate part of the acid or to use it in other industries; this made the construction and operation of such plants more complicated and more expensive.

Great difficulties also arose in the selection of materials for equipment that are resistant in aggressive environments. For this reason, the bulk of the currently operating hydrolysis plants were built by the method of hydrolysis with dilute sulfuric acid.

The first experimental hydrolysis and alcohol plant in the USSR was commissioned in January 1934 in the city of Cherepovets. The initial indicators and technical design of this plant were developed by the Department of Hydrolysis Production of the Leningrad Forestry Academy in 1931-1933. On the basis of data from the operation of the pilot plant, the construction of industrial hydrolysis and alcohol plants in the USSR was started. The first industrial hydrolysis and alcohol plant was launched in Leningrad in December 1935. Following this plant in the period 1936-1938. the Bobruisk, Khorsky and Arkhangelsk hydrolysis and alcohol plants were commissioned. During the Second World War and after it, many large factories were built in Siberia and the Urals. At present, the design capacity of these plants as a result of improving technology has been exceeded by 1.5-2 times.

The main raw material for these factories is coniferous wood in the form of sawdust and chips, coming from neighboring sawmills, where it is obtained by crushing sawmill waste - slabs and slats in chippers. In some cases, coniferous firewood is also crushed.

The scheme for obtaining monosaccharides at such plants is shown in Fig. 76.

Chopped coniferous wood from the raw material warehouse is transported by conveyor 1 into the guide funnel 2 and further down the throat-

|

|

The fault of the hydrolysis apparatus 3. It is a vertical steel cylinder with upper and lower cones and necks. The inner surface of such hydrolysis apparatus covered with acid-resistant ceramic or graphite tiles or bricks fixed on a layer of concrete 80-100 thick mm. The joints between the tiles are filled with acid-resistant putty. The upper and lower necks of the hydrolysis apparatus from the inside are protected from the action of hot diluted sulfuric acid by a layer of acid-resistant bronze. The useful volume of such hydrolysis apparatuses is usually 30-37 At3, but sometimes hydrolysis apparatuses with volumes of 18, 50 and 70 are also used. m3. The inner diameter of such hydrolysis apparatus is about 1.5, and the height is 7-13 m. Into the upper cone of the hydrolysis apparatus during hydrolysis through the pipe 5 diluted sulfuric acid heated to 160-200 ° is fed.

A filter is installed in the lower cone 4 for the selection of the obtained hydrolyzate. Hydrolysis in such devices is carried out periodically.

As already mentioned above, the hydrolysis apparatus is loaded with crushed raw materials through a guide funnel. When loading raw materials through a pipe 5 diluted sulfuric acid heated to 70-90 ° is supplied, which wets the raw material, contributing to its compaction. With this loading method, 1 m3 the hydrolysis apparatus fits about 135 kg sawdust or 145-155 kg Chips, calculated as absolutely dry wood. At the end of the loading, the contents of the hydrolysis apparatus are heated with live steam entering its lower cone. As soon as the temperature of 150-170 ° is reached, 0.5-0.7% - sulfuric acid, heated to 170-200 °, begins to flow into the hydrolysis apparatus through pipe 5. Simultaneously formed hydrolyzate through the filter 4 begins to be discharged into the evaporator b. The hydrolysis reaction in the hydrolysis apparatus lasts from 1 to 3 hours. The shorter the hydrolysis time, the higher the temperature and pressure in the hydrolysis apparatus.

In the process of hydrolysis, wood polysaccharides are converted into the corresponding monosaccharides, which dissolve in hot dilute acid. To protect these monosaccharides from decomposition at a high temperature, the hydrolyzate containing them is continuously withdrawn through a filter throughout the cooking process. 4 And quickly cooled in an evaporator 6. Since, according to the process conditions, it is a hydrolyzable plant material. the hydrolysis apparatus "must be filled with liquid all the time, the given level is maintained by hot acid flowing through pipe 5,

This method of operation is called percolation. The faster the percolation proceeds, i.e. the faster the hot acid flows through the hydrolysis apparatus, the faster the sugar formed is removed from the reaction space and the less it decomposes. On the other hand, the faster the percolation proceeds, the more is spent on cooking hot acid and the lower is the concentration of sugar in the hydrolyzate and, accordingly, the more steam and acid are consumed for cooking.

In practice, to obtain sufficiently high sugar yields (at an economically acceptable concentration in the hydrolyzate), one has to choose some average percolation conditions. Usually they stop at the sugar outlet at 45-50% of the weight of absolutely dry wood with a sugar concentration in the hydrolyzate of 3.5-3.7% - These optimal reaction conditions correspond to the selection through the lower filter from the hydrolysate - 12-15 m3 hydrolyzate for 1 T absolutely dry wood loaded into the hydrolysis apparatus. The amount of hydrolyzate withdrawn for cooking for each ton of hydrolyzed raw materials is called the outflow hydromodule, and it is one of the main indicators of the hydrolysis regime used at the plant.

In the process of percolation between the upper and lower necks of the hydrolysis apparatus, a certain pressure difference arises, which contributes to the compression of the raw material as the polysaccharides contained in it dissolve.

Compression of the raw material leads to the fact that at the end of cooking, the remaining undissolved lignin takes up about 25% of the initial volume of the raw material. Since, according to the reaction conditions, the liquid must cover the raw material, its level decreases accordingly during the cooking process. Control over the level of liquid during the cooking process is carried out using a weight meter 30, showing the change in the total weight of raw materials and liquid in the hydrolysis apparatus.

At the end of cooking, lignin remains in the apparatus, containing 1 kg dry matter 3 kg diluted sulfuric acid, heated to 180-190 °.

From the hydrolysis apparatus, lignin is discharged into a cyclone 22 according to work 21. For this purpose, the valve is quickly opened. 20, connecting the inner space of the hydrolysis apparatus with the cyclone 22. Due to the rapid decrease in pressure between the lignin pieces, the superheated water contained in it instantly boils, forming large volumes of steam. The latter tears up the lignin and carries it in the form of a suspension along the pipe. 21 into the cyclone 22. Pipe 21 approaches the cyclone tangentially, due to which a jet of steam with lignin, bursting into the cyclone, moves along the walls, making a rotational motion. Lignin is thrown by centrifugal force to the side walls and, losing speed, falls to the bottom of the cyclone. Lignin-free steam through the central pipe 23 released into the atmosphere.

Cyclone 22 usually a vertical steel cylinder with a volume of about 100 m3, equipped with a side door 31 and rotating stirrer 25, which assists in unloading lignin from the bottom of the cyclone onto a belt or scraper conveyor 24.

To protect against corrosion, the inner surface of the cyclones is sometimes protected with a layer of acid-resistant concrete. As mentioned above, during the percolation process, heated diluted sulfuric acid is fed into the upper cone of the hydrolysis apparatus. It is prepared by mixing in an acid-proof mixer 17 superheated water supplied through the pipe 28, with cold concentrated sulfuric acid coming from a measuring tank 19 via a piston acid pump 18.

Since cold concentrated sulfuric acid weakly corrodes iron and cast iron, these metals are widely used for the manufacture of tanks, pumps and pipelines for its storage and transportation to the mixer. Similar materials are used to supply overheated iodine to the mixer. To protect the mixer walls from corrosion, use phosphorous bronze, graphite or plastic mass - fluoroplastic 4. The last two are used for the internal lining of mixers and give the best results.

The finished hydrolyzate from the hydrolysis apparatus enters the evaporator 6 high pressure. It is a steel vessel, working under pressure and lined inside with ceramic tiles, like a hydrolysis apparatus. There is a cover in the upper part of the evaporator with a capacity of 6-8 g3. The evaporator is maintained at a pressure of 4-5 atm lower than in the hydrolysis apparatus. Due to this, the hydrolyzate entering it instantly boils, partially evaporates, and cools down to 130-140 °. The resulting steam is separated from the hydrolyzate droplets and through the pipe 10 enters the reshoer (heat exchanger) 11, where it condenses. Partially cooled hydrolyzate from evaporator 6 through pipe 7 enters the evaporator 8 low pressure, where it is cooled to 105-110 ° as a result of boiling at a lower pressure, usually not exceeding one atmosphere. Steam generated in this evaporator through the pipe 14 served in the second resofer 13, where also condenses. Condensates from resofers 11 and 13 contain 0.2-0.3% furfural and are used for its isolation in special installations, which will be discussed below.

Heat contained in the steam that comes out of the evaporators 6 and 8, used to heat the water entering the mixer 17. For this purpose from the tank 16 circulating water pump 1b Warm water, obtained from the distillation department of the hydrolysis plant, is fed to a low pressure resoffer 13, where it heats up from 60-80 ° to 100-110 °. Then along the pipe 12 heated water passes through a high pressure resoffer 11, where steam at a temperature of 130-140 ° is heated to 120-130 °. Then the water temperature is increased to 180-200 ° in the water heating column 27. The latter is a vertical steel cylinder with a bottom and top cover, designed for a working pressure of 13-15 atm.

Steam is fed into the water heater through a vertical pipe 26, at the end of which 30 horizontal discs are fixed 2b. Steam from the pipe 26 passes through the slots between the individual discs into a column filled with water. The latter is continuously fed into the column through the lower nozzle, mixed with steam, heated to a predetermined temperature and through a pipe 28 enters the mixer 17.

Hydrolysis machines are installed on a special foundation in a row of 5-8 pcs. In large factories, their number is doubled and installed in two rows. Hydrolyzate pipelines are made of red copper or brass. The fittings, consisting of valves and valves, are made of phosphoric or passport bronze.

The above hydrolysis process is batchwise. Currently, new designs of hydrolysis plants are being tested - devices of continuous action, into which, with the help of special feeders, crushed wood is continuously fed, lignin and hydrolyzate are continuously removed.

Work is also underway to automate batch hydrolysis apparatus. This event allows you to more accurately observe the preset cooking mode and at the same time facilitates the work of cooks.

Acid hydrolyzate from low pressure evaporator 8 (fig. 76) along the pipe 9 served in the apparatus for its subsequent processing. The temperature of this hydrolyzate is 95-98 °. It contains (in%):

Sulfuric acid. ... ... ………………………………………………………………………………………… .. 0.5 -0.7:

Hexose (glucose, mannose, galactose) ……………………………………………………… .. 2.5 -2.8;

Pentose (xylose, arabinose) ………………………………………………………………………. 0.8 -1.0;

Volatile organic acids (formic, acetic) …………………………… .. 0.24-0.30;

Non-volatile organic acids (levulinic). ... 0.2 -0.3;

Furfural ……………………………………………………………………………………………………. 0.03-0.05;

Oxymethylfurfural ……………………………………………………………………………………. 0.13-0.16;

Methanol. …………………………………………………………………………………………………… .. 0.02-0.03

Colloidal substances (lignin, dextrins), ash substances, terpenes, resins, etc. are also present in the hydrolysates. The content of monosaccharides in plant hydrolysates in precise chemical studies is established by quantitative paper chromatography.

In factory laboratories, for mass express determinations of sugars, their ability in an alkaline medium to reduce complex compounds of copper oxide with the formation of copper oxide is used:

2 Cu (OH) 2 Cu5 O + 2 H2 O + 02.

By the amount of the formed copper oxide, the co-i-fusion of monosaccharides in the solution is calculated.

This method for determining sugars is conditional, so Furfural, oxymethylfurfural, dextrins, colloidal lignin are also reduced to nitrous oxide simultaneously with monosaccharides. These impurities interfere with the determination of the true sugar content of the hydrolysates. The general error here reaches 5-8%. Since the correction for these impurities requires a large expenditure of labor, it is usually not done, and the resulting sugars, in contrast to monosaccharides, are called reducing substances or abbreviated RV. At the factory, the accounting for the amount of sugar produced in the hydrolyzate is taken into account in tons of RV.

To obtain ethyl alcohol, hexose (glucose, mannose and galactose) is fermented with alcohol-forming yeast - saccharomycetes or schizosaccharomycetes.

The total equation of alcoholic fermentation of hexoses

C (i Hf, 06 - 2 С2 НГ) ОН + 2 С02 Hexose ethanol

Shows that during this process, theoretically, for every 100 kg sugar should be 51.14 kg, or about 64 l 100% ethyl alcohol and about 49 kg carbon dioxide.

Thus, during alcoholic fermentation of hexoses, two main products are obtained in almost equal amounts: ethanol and carbon dioxide. To carry out this process, the hot acidic hydrolyzate must be subjected to the following treatment:

1) neutralization; 2) release from suspended solids; 3) cooling to 30 °; 4) enrichment of the hydrolyzate with nutrients necessary for the life of yeast.

The acidic hydrolyzate has a pH of 1 to 1.2. A medium suitable for fermentation should have a pH of 4.6-5.2. In order to impart the necessary acidity to the hydrolysate, the free sulfuric acid and a significant part of the organic acids contained in it must be neutralized. If all the acids contained in the hydrolyzate are conventionally expressed in sulfuric acid, then its concentration will be about 1%. The residual acidity of the hydrolyzate at pH = 4.6-5.2 is about 0.15%.

Therefore, in order to obtain the required concentration of hydrogen ions in the hydrolyzate, 0.85% of acids must be neutralized in it. At the same time, free sulfuric, formic and part of the acetic acid are completely neutralized. Levulinic acid and a small part of acetic acid remain free.

The hydrolyzate is neutralized with milk of lime, that is, with a suspension of calcium oxide hydrate in water with a concentration of 150-200 g of CaO per liter.

The scheme for the preparation of milk of lime is shown in Fig. 77.

Quicklime CaO is continuously fed into the hopper of the rotating lime drum 34.

At the same time, the required amount of water is fed into the drum. When the drum rotates, the quicklime, binding water, goes into calcium oxide hydrate. The latter is dispersed in water, forming a suspension. Unreacted lime pieces are separated from the milk of lime at the end of the drum and dropped into the trolley. The milk of lime together with the sand flows through the pipe to the sand separator 35.

The latter is a horizontally located iron trough with transverse partitions and a longitudinal shaft with blades.

Quicklime CaO is continuously fed into the hopper of the rotating lime drum 34.

At the same time, the required amount of water is fed into the drum. When the drum rotates, the quicklime, binding water, goes into calcium oxide hydrate. The latter is dispersed in water, forming a suspension. Unreacted lime pieces are separated from the milk of lime at the end of the drum and dropped into the trolley. The milk of lime together with the sand flows through the pipe to the sand separator 35.

The latter is a horizontally located iron trough with transverse partitions and a longitudinal shaft with blades.

The milk of lime in this apparatus slowly flows from right to left and further along the pipe 36 merges into the collection 2.

The sand slowly settles between the sand separator baffles and is removed from the apparatus using slowly rotating blades. Before the milk of lime enters the neutralizer, it is mixed with a predetermined amount of ammonium sulfate, the solution of which comes from the tank 37. When lime milk is mixed with ammonium sulfate, the reaction proceeds

Ca (OH) 3 + (NH4) 2 SO4-> CaSO4 + 2 NH, OH, as a result of which part of the lime is bound by sulfuric acid of ammonium sulfate and crystals of poorly soluble dihydrate calcium sulfate CaS04-2H20 are formed. At the same time, ammonia is formed, which remains in a dissolved state in the milk of lime.

The small crystals of gypsum present in the milk of lime during subsequent neutralization are the centers of crystallization of the resulting gypsum and protect it from the formation of supersaturated solutions in the neutralized hydrolyzate. This event is important for the subsequent distillation of alcohol from the mash, since supersaturated gypsum solutions in the mash cause gypsum plaster of the mash columns and quickly disable them. This method of work is called neutralization with directional crystallization of gypsum.

Simultaneously with milk of lime into a neutralizer 5 A slightly acidic aqueous superphosphate extract from a measuring tank is fed 38.

Salts are given to the neutralizer at the rate of 0.3 kg ammonium sulfate and 0.3 kg superphosphate per 1 m3 hydrolyzate.

Neutralizer 5 (with a capacity of 35-40 m 3) is a steel tank lined with acid-resistant ceramic tiles and equipped with vertical stirrers and brake blades fixed motionlessly on the tank walls. Neutralization at hydrolysis plants was previously carried out periodically. At present, it is being supplanted by more perfect continuous neutralization. In fig. 77 shows the last diagram. The process is carried out in two series-connected neutralizers 5 and 6, which have the same device. Acid hydrolyzate is continuously fed through pipe 1 to the first neutralizer, where milk of lime and nutritious salts are simultaneously supplied. Control over the completeness of neutralization is carried out by measuring the concentration of hydrogen ions using a potentiometer 3 with an antimony or glass electrode 4. The potentiometer continuously records the pH of the hydrolyzate and automatically adjusts it within the specified limits by sending electrical impulses to the reversing motor connected to the shut-off valve on the pipe that feeds the milk of lime to the first neutralizer. In neutralizers, the neutralization reaction proceeds relatively quickly and the process of gypsum crystallization from a supersaturated solution proceeds relatively slowly.

Therefore, the rate of fluid flow through the neutralization unit is due to the second process, which requires 30-40 min.

After this time, the neutralized hydrolyzate, called "neutralized", enters the settler 7 of semi-continuous or continuous operation.

The semi-continuous process consists in the fact that the neutralizer flows through the sump continuously, and the gypsum that settles to the bottom is removed periodically, as it accumulates.

With continuous operation of the sump, all operations are performed continuously. Before going down the drain, sludge 8 in the receiver it is additionally rinsed with water. The latter method has not yet become widespread due to some production difficulties.

Gypsum sludge from the sump usually consists of half of calcium sulfate dihydrate and half of lignin and humic substances precipitated from the hydrolyzate. In some hydrolysis plants, gypsum sludge is dewatered, dried and fired, turning into alabaster. They are dehydrated in drum vacuum filters, and dried and fired in rotary drum furnaces heated by flue gases.

The neutralizer, freed from suspended particles, is cooled in the refrigerator before fermentation 10 (fig. 77) from 85 to 30 °. For this purpose, spiral or plate heat exchangers are usually used, which have a high heat transfer coefficient and small dimensions. When cooled, resinous substances are released from the neutralizer, which settle on the walls of the heat exchangers and gradually contaminate them. For cleaning, the heat exchangers are periodically turned off and washed with a 2-4% hot aqueous solution of sodium hydroxide, which dissolves resinous and humic substances.

Neutralized, purified and cooled hydrolyzate.

The wood must is fermented with special sprt-forming yeast acclimatized in this environment. Fermentation proceeds according to a continuous method in a battery of fermentation tanks connected in series 11 and 12.

Yeast suspension, containing about 80-100 g of compressed yeast per liter, is fed in a continuous flow through a pipe 15 in yeast 44 and then to the top of the first, or head, fermentation vat 11. Chilled wood wort is fed into the yeast tank simultaneously with the yeast suspension. For each cubic meter of yeast suspension, 8-10 m3 of wort is supplied to the fermentation tank.

Yeasts contained in the environment of hexose Sakharov, with the help of a system of enzymes, they break down sugars, forming ethyl alcohol and carbon dioxide. Ethyl alcohol passes into the surrounding liquid, and carbon dioxide is released on the surface of the yeast in the form of small bubbles, which gradually 'increase in volume, then gradually float to the surface of the vat, carrying away the yeast adhering to them.

When in contact with the surface, the bubbles of carbon dioxide burst, and the yeast, which has a specific gravity of 1.1, that is, greater than that of the wort (1.025), sinks down until it is again raised by carbon dioxide to the surface. The continuous movement of the yeast up and down aids in the movement of streams of liquid in the fermentation tank, creating stirring or "fermentation" of the liquid. Carbon dioxide released on the surface of the liquid from the fermentation tanks through the pipe 13 enters the plant for the production of liquid or solid carbon dioxide, is used for the production of chemical products (for example, urea) or is released into the atmosphere.

Partially fermented wood wort together with yeast is transferred from the head fermentation tank to the tail vat 12, Where fermentation ends. Since the concentration of sucrose in the tail vat is low, fermentation in it is less intense, and part of the yeast, without having time to form bubbles of carbon dioxide, settles to the bottom of the vat. To prevent this, in the tail vat, forced mixing of the liquid is often arranged with mixers or centrifugal pumps.

Fermented or fermented liquid is called mash. At the end of fermentation, the mash is transferred to the separator 14, working on the principle of a centrifuge. The mash entering it, together with the yeast suspended in it, begins to rotate at a speed of 4500-6000 rpm. Centrifugal force due to the difference in specific gravity of the mash and yeast separates them. The separator divides the liquid into two streams: the larger one, which does not contain yeast, enters the funnel 16 and the smaller one containing yeast enters through the funnel into the pipe 15. Typically, the first stream is 8-10 times larger than the second. Down the pipe 15 the yeast slurry is returned to the head fermentation tank 11 Through yeast 44. The wort discarded and freed from yeast is collected in an intermediate mash collector 17.

With the help of separators, the yeast is constantly circulated in a closed system of the fermentation plant. Separator capacity 10- 35 m3 / hour.

During fermentation and especially during separation, part of the humic colloids contained in the wood wort coagulates, forming heavy flakes that slowly settle to the bottom of the fermentation tanks. In the bottoms of the vats, there are fittings through which the sediment is periodically discharged into the sewer.

As mentioned above, the theoretical yield of alcohol from 100 kg fermented hexoses is 64 l. However, practically due to education due to Sakharov by-products (glycerin, acetaldehyde, succinic acid, etc.), as well as due to the presence of impurities harmful to yeast in the wort, the alcohol yield is 54-56 l.

To obtain good alcohol yields, the yeast must be kept active at all times. To do this, you should carefully maintain the set fermentation temperature, the concentration of hydrogen ions, the required purity of the wort, and leave a small amount of hexoses, the so-called "unkind" (usually no more than 0.1% 'sugar in solution) in the mash before entering the separator. Due to the presence of unkindness, the yeast remains in an active form all the time.

Periodically, the hydrolysis plant is shut down for scheduled preventive or major repairs. During this time, the yeast should be kept alive. For this, the yeast suspension is thickened using separators and poured with cold wood wort. At low temperatures, fermentation slows down dramatically and the yeast consumes significantly less sugar.

Fermentation tanks with a capacity of 100-200 m3 are usually made of sheet steel or, less often, of reinforced concrete. The duration of fermentation depends on the concentration of yeast and ranges from 6 to 10 hours. It is necessary to monitor the purity of the production culture of yeast and protect it from infection by foreign harmful microorganisms. For this purpose, all equipment must be kept clean and periodically sterilized. The simplest method of sterilization is to steam all equipment and especially pipelines and pumps with live steam.

At the end of fermentation and separation of yeast, the alcoholic brew contains from 1.2 to 1.6% ethyl alcohol and about 1% pentose Sakharov.

Alcohol is isolated from the brew, cleaned and strengthened in a three-column brew rectifier, consisting of a brew 18, rectification 22 and methanol 28 columns (Fig. 77).

Mash from the collection 17 pump fed through a heat exchanger 41 on the feed plate of the mash column 18. Flowing down the plates of the exhaustive part of the mash column, the mash meets a rising steam on its way. The latter, gradually enriching with alcohol, passes into the upper, strengthening part of the column. The mash flowing downward is gradually freed from alcohol, and then from the still side of the column 18 through the pipe 21 goes into heat exchanger 41, where he heats the mash entering the column to 60-70s. Then the mash is heated to 105 ° in a column with live steam flowing through a pipe 20. The brew, freed from alcohol, is called "bard". Down the pipe 42 Barda comes out of the bardy heat exchanger 41 and is sent to the yeast shop to obtain fodder yeast from pentoses. This process will be further discussed in detail.

The mash column in the upper reinforcing part ends with a dephlegmator 19, in which vapors are condensed - an alcohol mixture coming from the upper tray of the column.

In 1 m3 of mash at a temperature of 30 °, about 1 m3 of carbon dioxide formed during fermentation dissolves. When heating mash in a heat exchanger 41 and with live steam in the lower part of the mash column, dissolved carbon dioxide is released and, together with alcohol vapor, rises into the strengthening part of the column and then into the reflux condenser 19. Non-condensable gases are separated through air vents installed on the alcohol condensate pipelines after the refrigerators. Low-boiling fractions consisting of alcohol, aldehydes and ethers pass through a reflux condenser 19 and finally condense in the refrigerator 39y From where, in the form of reflux, they flow back into the column through a water seal 40. Non-condensable gases consisting of carbon dioxide before leaving the refrigerator 39 pass through an additional condenser or are washed in a scrubber with water to capture the last residues of alcohol vapors.

On the upper trays of the beer column, the liquid phase contains 20-40% alcohol.

Condensate through the pipe 25 enters the feed plate of the rectification column 22. This column works similarly to the mash column, but at higher alcohol concentrations. To the bottom of this column along the pipe 24 hot steam is supplied, which gradually boils alcohol from the alcohol condensate flowing down to the bottom of the column. A liquid freed from alcohol, called a luther, down the pipe 23 goes down the drain. The alcohol content in vinasse and luther is no more than 0.02%.

Over the top plate rectification column a dephlegmator is installed 26. The vapors not condensed in it are finally condensed in the condenser 26a and flow back into the column. Part of the low-boiling fractions is taken through a pipe 43 in the form of an ether-aldehyde fraction, which is returned to the fermentation tanks if it is not used.

To free ethyl alcohol from volatile organic acids, the column is fed from the tank 45 10% sodium hydroxide solution, which neutralizes acids on the middle trays of the reinforcing part of the column. In the middle part of the distillation column, where the alcohol strength is 45-50%, fusel oils accumulate, which are taken through the pipe 46. Fusel oils are a mixture of higher alcohols (butyl, propyl, amyl) formed from amino acids.

Ethyl alcohol, freed from ethers and aldehydes, as well as fusel oils, is taken using a comb from the upper plates of the reinforcing part of the rectification column and through a pipe 27 enters the feed plate of the methanol column 28. The raw alcohol coming from the distillation column contains about 0.7% methyl alcohol, which was formed during the hydrolysis of plant raw materials and, together with monosaccharides, got into the wood wort.

Methyl alcohol is not formed during fermentation of hexoses. According to the technical specifications for ethyl alcohol produced by hydrolysis plants, it must contain no more than 0.1% methyl alcohol. Studies have shown that methyl alcohol is most easily separated from raw alcohol with a minimum water content in it. For this reason, raw alcohol with a maximum strength (94-96% ethanol) is fed to the methanol column. Above 96%, ethyl alcohol cannot be obtained on conventional rectification columns, since this concentration corresponds to the composition of a non-separable water-alcohol mixture.

In a methanol column, the low-boiling fraction is methanol, which rises to the top of the column and is strengthened in a reflux condenser 29 and along the pipe 30 is discharged into the collectors of the methanol fraction containing about 80% methanol. To release commercial 100% methanol, a second methanol column is installed, not shown in Fig. 77.

Ethyl alcohol, flowing down the plates, goes down to the bottom of the methanol column 28 and along the pipe 33 merges into finished product receivers. The methanol column is heated with deaf steam in a remote heater 31, which is installed in such a way that, according to the principle of communicating vessels, its annular space is filled with alcohol. The water vapor entering the heater heats the alcohol to a boil and the resulting alcohol vapors are used to heat the column. Steam entering the heater 31, condenses in it and in the form of condensate is fed into the collectors of clean water or drained into the sewer.

The amount and strength of the obtained ethyl alcohol is measured in special equipment (flashlight, control shell, alcohol measure). Ethyl alcohol is pumped from the measuring tank with a steam pump outside the main building - to stationary tanks located in the alcohol warehouse. From these tanks, as required, commercial ethyl alcohol is poured into railway tanks, in which it is transported to places of consumption.

The technological process described above makes it possible to obtain from 1 T absolutely dry coniferous wood 150-180 l 100% ethyl alcohol. Moreover, 1 dcl alcohol consumption

Absolutely dry wood in kg. ... ... ... ... 55-66;

TOC o "1-3" h z sulfuric acid - moohydrate in kg … . 4,5;

Quicklime, 85% kg…………………………………………………. 4,3;

A pair of technological 3- and 16-atmospheric

In megacalories. ……………………………………………………………………… .. 0.17-0.26;

Water in m3 …………………………………………………………………………………………. 3.6;

Elekgrozner in kWh…………………………………………………………………….. 4,18

The annual productivity of the hydrolysis-alcohol plant of average capacity for alcohol is 1-1.5 mln. gave. In these factories, ethyl alcohol is the main product. As already mentioned, at the same time, solid or liquid carbon dioxide, furfural, fodder yeast, and lignin processing products are produced from the waste of the main production at the hydrolysis-alcohol plant. These productions will be discussed further.

In some hydrolysis plants, which receive furfural or xylitol as the main product, after the hydrolysis of pentose-rich hemicelluloses, a difficult-to-hydrolyzable residue, consisting of cellulose and lignin, called cellolignin, remains.

Cellolignin can be hydrolyzed by the percolation method as described above, and the resulting hexose hydrolyzate, usually containing 2-2.5% sugars, can be processed as described above into technical ethyl alcohol or feed yeast. According to this scheme, cotton husk, corn stalk, oak oak, sunflower husk, etc. are processed. Such a production process is economically profitable only with cheap raw materials and fuel.

Hydrolysis alcohol plants usually produce technical ethyl alcohol, which is used for subsequent chemical processing. However, if necessary, this alcohol

relatively easily purified by additional rectification and oxidation with an alkaline permanganate solution. After such cleaning, ethyl alcohol is quite suitable for food purposes.

Nowadays, many people know how to create methanol even with their own hands at home. Including engaged in the preparation of alcohol from sawdust. It is the production of alcohol from sawdust that is considered the simplest and most economical of all the other methods known today. At the same time, it seems complicated and time-consuming only at first glance. In fact, repeating this process will be easy enough even for a beginner. The main thing is to know all the basic principles of the manufacture of methyl alcohol, as well as take into account some of the tricks of the procedure, which are revealed to everyone by professionals. The standard technology for the production of the discussed chemical at home usually consists of several main stages at once. To begin with, malt is obtained from grain crops, then a paste is cooked from slightly spoiled potatoes, as a result of which the starch is processed.

The next stage is fermentation. On it, yeast is already added to the previously prepared mixture. The higher the ambient temperature, the faster it will be possible to overcome the stage under discussion. But it is able to complete on its own even under normal natural conditions. Of course, in the event that quality yeast was chosen. The penultimate stage is called "distillation". It can be called the most laborious and time consuming. For this stage, a special apparatus is always required, which, by the way, modern craftsmen easily make with their own hands. And finally, there is only cleaning left. This is the very last step in the production of alcohol at home. The product is almost ready, only it lacks the desired transparency. It will be possible to achieve it with the help of the most common potassium permanganate, with which the liquid is infused for 24 hours. Finally, all that remains is to filter the product.

Since recently the amount of fossil raw materials that are suitable for the production of alcohol at home has been gradually decreasing, it became necessary to find new options. As you know, there is a shortage of grain, so it was necessary to find a worthy alternative to it. And it was quickly found - it is sawdust. This raw material is currently the most affordable for everyone. Finding it is not difficult. Last but not least, sawdust is inexpensive. And in some cases, they can be found completely free of charge. It is not surprising that the discussed raw materials are very popular among all those involved in the production of alcohol at home. True, the manufacture of this substance requires certain skills from a person, as well as the acquisition of some additional equipment.

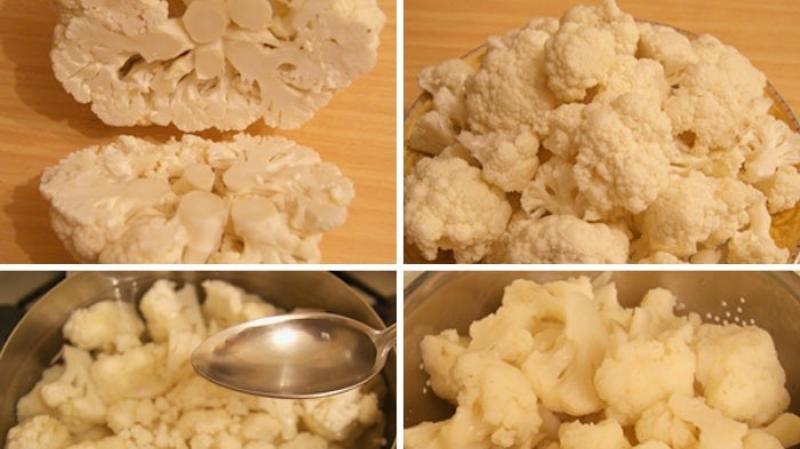

First of all, you will need to prepare sawdust. For example, 1 kilogram of the original product. It is very important that the sawdust is thoroughly crushed. They will need to be thoroughly dried before starting to produce methanol. It is best to refuse to use an oven and other similar options for this purpose. It will be enough to pour a thin layer of sawdust onto a clean newspaper in a dark, well-ventilated room and leave it that way for several days. Of course, the raw materials should also not contain any impurities and dirt. Experts note that hardwood sawdust is best suited for this process. But it is better not to use raw materials from conifers.

Through the refrigerator, in which sublimation and electrolyte will be carried out, which is perfect for sulfuric acid, carefully dried sawdust is sent to a convenient flask or other similar container. They must fill it 2/3 of the total. Next, you need to heat the mass to 150 degrees. The finished liquid usually has a slight bluish tint. Of course, you shouldn't forget about using a quality catalyst. For example, you can use aluminum oxide - parts of corundum. You can pour the next portion into the used vessel immediately after the liquid in it turns black. It is very important to protect your respiratory organs with a respirator or special mask. It is best to think about durable gloves as well. The room in which alcohol is made from sawdust should be spacious and thoroughly ventilated. You shouldn't do this in the kitchen, as there are food around.

The finished substance can be used as fuel and for any other similar purposes. But it is not recommended to use the resulting alcohol inside and use it for further preparation of alcoholic beverages from it. From just one kilogram of dried sawdust, you can get about half a liter (slightly less) of finished methanol.

The production of alcohol from potatoes, grain, molasses, sugar beets requires the consumption of large quantities of these valuable raw materials. Replacing such raw materials with cheaper ones is one of the sources of food savings and reducing the cost of alcohol. Therefore, in recent years, the production of technical ethyl alcohol from non-food raw materials has significantly increased: wood, sulfite liquors and synthetically from ethylene-containing gases.

Alcohol production from wood

The hydrolysis industry produces a number of products from plant waste containing cellulose, in particular from wood waste: ethyl alcohol, feed yeast, glucose, etc.

In hydrolysis plants, cellulose is hydrolyzed with mineral acids to glucose, which is used for fermentation into alcohol, growing yeast and releasing it in crystalline form. There are hydrolysis plants of various profiles: hydrolysis-alcohol, hydrolysis-yeast, hydrolysis-glucose. The hydrolysis industry is of great economic importance; it is due to the fact that valuable products are obtained from low-value plant waste. In particular, 170-200 liters of ethyl alcohol is obtained from 1 ton of absolutely dry coniferous wood, for the production of which 0.7 tons of grain or 2 tons of potatoes would be required.

The hydrolysis industry comprehensively processes wood, as a result of which, in addition to ethyl alcohol, other valuable products are obtained at hydrolysis-alcohol plants: furfural, lignin, liquid carbon dioxide, fodder yeast.

Raw materials for hydrolysis production

The raw material for hydrolysis production is wood in the form of various wastes from the forestry and woodworking industries: sawdust, wood chips, shavings, etc. The moisture content of the wood ranges from 40 to 60%. Sawdust processed by hydrolysis plants usually has a moisture content of 40-48%. The dry matter of wood includes cellulose, hemicelluloses, lignin and organic acids.

Hemicelluloses of wood are composed of hexosans: mannan, galactan and pentosans: xylan, araban and their methylated derivatives. Lignin is a complex aromatic substance, its chemical composition and structure have not yet been established.

Chemical composition absolutely dry wood is shown in table 1.

In addition to wood, plant waste from agriculture is also used as a raw material for the hydrolysis industry: sunflower husk, corn cob, cotton husk, and cereal straw.

The chemical composition of agricultural plant waste is presented in Table 2.

Technological scheme of complex wood processing

The technological scheme of complex wood processing consists of the following stages: wood hydrolysis, neutralization and purification of the hydrolyzate; fermentation of hydrolysis wort, distillation of hydrolysis mash.

Shredded wood is subjected to hydrolysis with dilute sulfuric acid when heated under pressure. During hydrolysis, hemicelluloses and cellulose decompose. Hemicelluloses are converted into hexoses: glucose, galactose, mannose and pentoses: xylose and arabinose; cellulose into glucose. During hydrolysis, lignin remains as an insoluble residue.

The hydrolysis of wood is carried out in a hydrolysis apparatus - a steel cylindrical vessel. As a result of hydrolysis, a hydrolyzate is obtained containing about 2-3% of fermentable monosaccharides and an insoluble lignin residue. The latter can be used directly in the production of building boards, in brick production, when grinding cement, as a fuel; after appropriate processing, lignin can be used in the plastics industry, rubber industry, etc.

The resulting hydrolyzate is sent to an evaporator, where the vapor is separated from the liquid. The released vapor is condensed and used to isolate furfural, turpentine and methyl alcohol from it. Then the hydrolyzate is cooled to 75-80 ° C, neutralized in a neutralizer with milk of lime to pH 4-4.3, and nutritional salts for yeast (ammonium sulfate, superphosphate) are added. The resulting neutralizer is defended to free calcium sulfate and other suspended particles from the precipitate. The settled precipitate of calcium sulphate is separated, dried, roasted and alabaster is obtained, which is used in construction equipment. The neutralizer is cooled to 30-32 ° C and sent to fermentation. The hydrolyzate prepared in this way for fermentation is called wort. Fermentation of hydrolysis wort is carried out in a continuous way in fermentation tanks. In this case, the yeast is continuously circulating in the system; yeast is separated from the mash in separators. Carbon dioxide released during fermentation is used to release liquid or solid carbon dioxide. Mature brew containing 1.0-1.5% alcohol is sent for distillation and rectification to a brew rectifier and ethyl alcohol, methyl alcohol and fusel oil are obtained. Stillage obtained after distillation contains pentose and is used for growing feed yeast.

When processing according to the specified scheme, from 1 ton of absolutely dry coniferous wood, the following quantities of marketable products can be obtained:

- Ethyl alcohol, l ………………… .. 187

- Liquid carbon dioxide, kg …………… .. 70

- or solid carbon dioxide, kg ... ... ... 40

- Fodder yeast, kg …………… .. .. 40

- Furfural, kg …………………………… .9.4

- Turpentine, kg …………………………… 0.8

- Thermal insulation and construction ligno-plates, m 2…. 75

- Construction alabaster, kg …… ..225

- Fusel oil, kg ……………… ..0.3

Alcohol production from sulphite lye

In the production of cellulose from wood using the sulfite method, sulfite liquor is obtained as a waste - a brown liquid with the smell of sulfur dioxide. Chemical composition of sulfite liquor (%): water - 90, dry substances - 10, including lignin derivatives - lignosulfonates - 6, hexose - 2, pentose -1, volatile acids, furfural and other substances - about 1. For a long time sulfite liquor released into rivers, they polluted the water and destroyed fish in reservoirs. At present, we have a number of factories for the complex processing of sulfite liquor into ethyl alcohol, fodder yeast and sulfite-bard concentrates. The production of alcohol from sulfite liquors consists of the following stages: preparation of sulfite liquor for fermentation, fermentation of sulfite-alkaline wort, distillation of mature sulfite brew.

Preparation of sulphite liquor for fermentation is carried out in a continuous manner. The lye is purged with air to remove volatile acids and furfural, which retard the fermentation process. The purged lye is neutralized with milk of lime and then kept to enlarge the precipitated crystals of calcium sulphate and sulphide; while adding nutrient salts for yeast (ammonium sulfate and superphosphate). Then the lye is defended. Settled sludge - sludge - is drained into the sewer, and the clarified liquor is cooled to 30-32 ° C. The liquor prepared in this way is called wort. The wort is sent to the fermentation section and fermented in the same way as wood hydrolysates, or the method with a movable nozzle is used. Movable packing refers to the cellulose fibers remaining in the liquor. The fermentation method with a movable nozzle is based on the property of some yeast strains to adsorb on the surface of cellulose fibers and form flakes of fibrous yeast mass, which in a mature mash quickly and completely settles to the bottom of the vat. Fermentation is carried out in a fermentation battery, which consists of a head and tail vats. In fermented wort, cellulose fibers with sorbed yeast are in continuous motion under the influence of emitted carbon dioxide. The fermented mash comes from the head vat to the tail vat, where the fermentation process ends, and the fibers with yeast settle to the bottom. The settled yeast-fibrous mass is returned by the pump to the head vat, where the wort is simultaneously served, and the mature brew containing 0.5-1% alcohol is sent to the distillation apparatus and ethyl alcohol, methyl alcohol and fusel oil are obtained. The stillage obtained after distillation contains pentoses and serves as a nutrient medium for growing feed yeast, which is then separated, dried and released in the form of dry yeast. After separation of yeast, vinasse containing lignosulfonates is evaporated to a dry matter content of 50-80%. The resulting product is called sulphite-grains concentrate and is used in the production of plastics, building materials, synthetic tanning agents for leather, in foundry and road construction.

A valuable aromatic substance - vanillin - can be obtained from sulfite-bardy concentrates.

The technological scheme for the complex processing of sulfite liquors into ethyl alcohol, fodder yeast and sulfite-barde concentrates is shown in Figure 2.

When processing sulfite liquors, the following is obtained in terms of 1 ton of spruce wood:

- Ethyl alcohol, l ……………… .. 30-50

- Methyl alcohol, l …………………… 1

- Liquid carbon dioxide, l ………… .. 19-25

- Dry feed yeast, kg…. 15

- Sulphite-bardy concentrates with a moisture content of 20%, kg…. 475

Synthetic alcohol production

The raw materials for the production of synthetic ethyl alcohol are refinery gases that contain ethylene. In addition, other ethylene-containing gases can be used: coke oven gas obtained from coal coking and associated petroleum gases.

Currently, synthetic ethyl alcohol is produced by two methods: sulfuric acid hydration and direct ethylene hydration.

Ethylene sulfate hydration

The production of ethyl alcohol by this method consists of the following processes: interaction of ethylene with sulfuric acid, in which ethyl sulfuric acid and diethyl sulfate are formed; hydrolysis of the resulting products with the formation of alcohol; separation of alcohol from sulfuric acid and its purification.

The raw material for sulphate hydration is gases containing 47-50% by weight. ethylene, as well as gases with a lower ethylene content. The process is carried out according to the scheme below.

Ethylene reacts with sulfuric acid in a vertical cylinder reaction column. Inside the column there are bubble cap trays with overflow glasses. An ethylene-containing gas is fed into the lower part of the column by a compressor, and 97-98% sulfuric acid is fed into the column from above for reflux. The gas, rising upward, on each tray bubbled through the liquid layer. Ethylene interacts with sulfuric acid by reactions:

A mixture of ethyl sulfuric acid, diethyl sulfate and unreacted sulfuric acid flows continuously from the reaction column. This mixture is cooled in a refrigerator to 50 ° C and sent to hydrolysis, in which the following reactions take place:

The monoethyl sulfate obtained from the second reaction is further decomposed to form another alcohol molecule.

Direct hydration of ethylene

The technological scheme for the production of ethyl alcohol by the method of direct hydration of ethylene is presented below.

The raw material for the direct hydration method is gas with a high ethylene content (94-96%). Ethylene is compressed by a compressor to 8-9 kPa. Compressed ethylene is mixed with steam in certain proportions. The interaction of ethylene with water vapor is carried out in a contact apparatus - a hydrator, which is a vertical steel hollow cylindrical column, which contains a catalyst (phosphoric acid deposited on an aluminosilicate).

A mixture of ethylene and steam at 280-300 ° C under a pressure of about 8.0 KPa is fed into a hydrator, in which the same parameters are maintained. In the interaction of ethylene with water vapor, in addition to the main reaction for the formation of ethyl alcohol, side reactions occur, as a result of which diethyl ether, acetaldehyde and ethylene polymerization products are obtained. The synthesis products carry away a small amount of phosphoric acid from the hydrator, which can subsequently have a corrosive effect on equipment and pipelines. To avoid this, the acid contained in the synthesis products is neutralized with alkali. The synthesis products after neutralization are passed through a salt separator, and then cooled in a heat exchanger and condensation of water-alcohol vapors is carried out. Get a mixture of aqueous-alcoholic liquid and unreacted ethylene. Unreacted ethylene is separated from the liquid in a separator. It is a vertical cylinder in which partitions are installed, dramatically changing the speed and direction of the gas flow. Ethylene from the separator is discharged into the suction line of the circulation compressor and is directed to mixing with fresh ethylene. The aqueous-alcoholic solution flowing out of the separator contains 18.5-19% vol. alcohol. It is concentrated in a stripping column and in the form of vapors is sent for purification to a distillation column. Alcohol is obtained with a strength of 90.5% vol. In the factories of synthetic alcohol, the method of direct hydration of ethylene is used.

The production of synthetic alcohol, regardless of the method of its production, is much more efficient than the production of alcohol from food raw materials. To obtain 1 ton of ethyl alcohol from potatoes or grain, it is necessary to spend 160-200 man-days, from oil refining gases only 10 man-days. The prime cost of synthetic alcohol is about four times less than the cost of alcohol from food raw materials.